Investing in this high-speed book shrink wrapping machine translates directly to enhanced productivity and reduced operational costs for the printing and packaging industries.

|

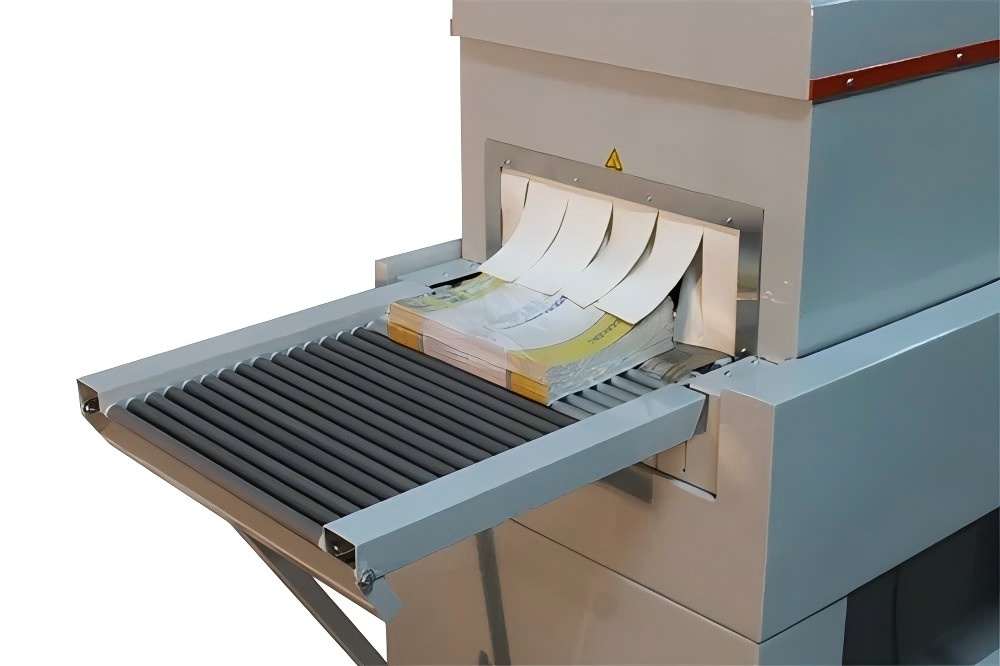

The modern printing and binding industry demands efficiency without sacrificing quality. Enter the High-Speed Book Shrink Wrapping Machine, the ultimate solution for publishers and binders seeking to streamline their final packaging process. This sophisticated automatic shrink wrap machine is specifically engineered for the book binding sector, handling everything from delicate paperbacks and spiral bound notebooks to robust hardcover books, journals, and diaries. By automating the entire process from feeding to collection, it eliminates tedious manual labor, significantly reduces costs, and ensures a pristine, retail-ready presentation that protects products during shipping and entices consumers on shelves. This advanced book packaging equipment comprises four seamlessly integrated units: an automatic book feeding table, a precision automatic sealing and cutting part, an efficient heat shrinking part, and a synchronized automatic book collecting table. The core advantage lies in its blistering high speed, capable of processing up to 80 pieces per minute. This remarkable throughput is made possible by a servo motor drive for the feeding system, ensuring precise and consistent movement. Electric sensors (electric eyes) and timers work in concert to automatically control the cutting size based on the book dimensions, guaranteeing a perfect fit for every item, whether it's a slim notepad or a thick glued bound volume.  At the heart of the sealing process is the innovative hot air knife. Featuring a Teflon coating and constant temperature heating, this critical component guarantees a clean, aesthetic, and strong seal every time. This technology eliminates common issues like adhesion or breakage, ensuring continuous thread and zero pollution on the finished product. The result is not just speed, but consistently good sealing and cutting effect that enhances the professional appearance of the packaged books and protects their contents from dirt and damage, making it ideal for packaging books & binding output.  The heat shrinking part utilizes an integrated thermal control system within a thermal cycle shrinker. This design allows for freely adjustable wind direction, ensuring uniform heat distribution around the book, regardless of its shape or size. Double layers of insulation within the tunnel maximize energy efficiency while achieving the perfect plastic sealing effect. This controlled environment guarantees the shrink film conforms tightly and smoothly to the book, creating a tamper-evident, protective barrier that showcases the product attractively while safeguarding it from dirt and debris during transit and storage.  Investing in this high-speed book shrink wrapping machine translates directly to enhanced productivity and reduced operational costs for the printing and packaging industries. The use of internationally renowned electronic control brands ensures exceptional equipment operation stability and a remarkably low failure rate, minimizing downtime. By replacing inefficient bagging and hand wrapping, this ideal process equipment eliminates bottlenecks, drastically cuts labor costs, and provides a scalable, reliable solution for achieving high-volume, retail-ready packaging for any book binding application. It's the cornerstone of a modern, efficient finishing line. |

| Tag:Book Shrink Wrapping Machine,Shrink Wrapping Machine,heat shrinking,packing machine |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!